In 2014, Shanghai Songjiang Shock Absorber Group Co., Ltd. supplied the acid and alkali resistant rubber joint products produced by Songjiang Group EPDM rubber for the Yanbu seawater desalination project in Saudi Arabia. This product is mainly resistant to sea water. In addition, our company also serves the sea water of Caofeidian Port. The desalination project supports seawater resistant rubber joint products.

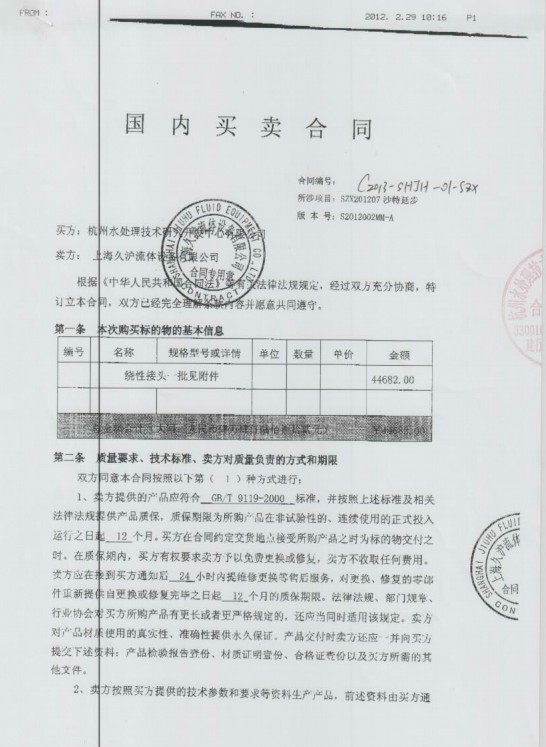

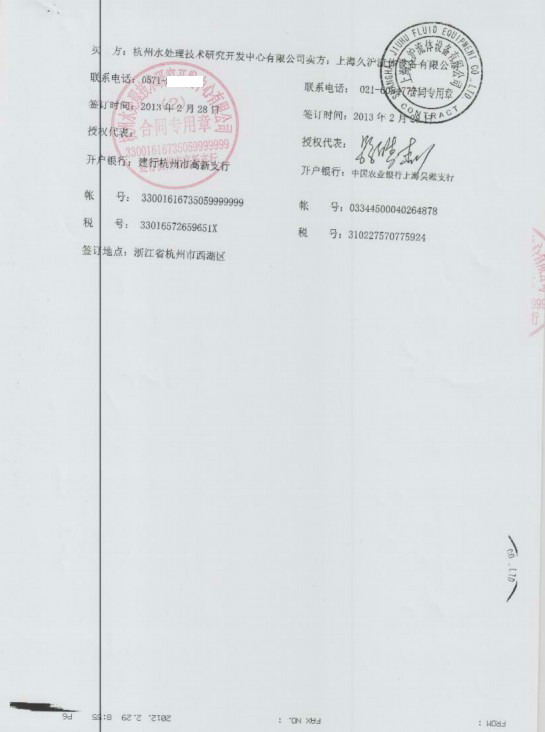

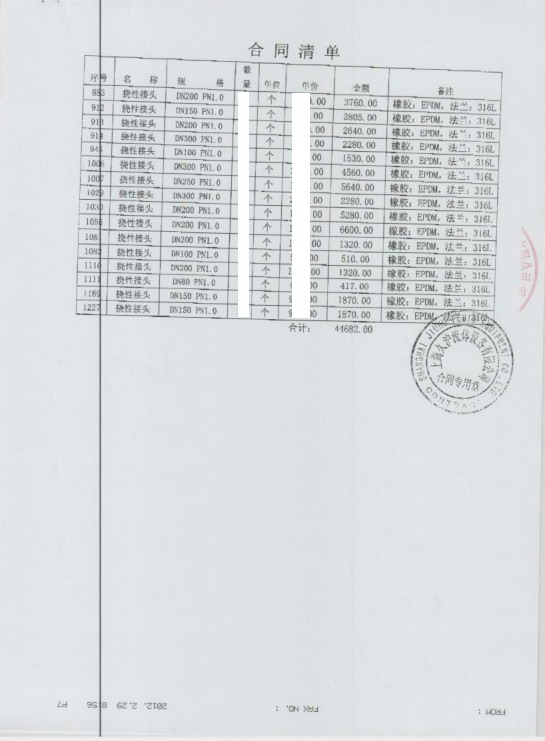

1. [Saudi Arabia Yanbu Seawater Desalination Project] A scanned copy of the supporting Songjiang EPDM rubber joint contract:

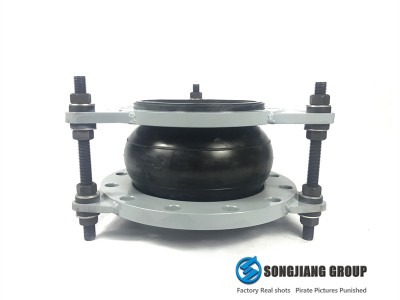

2. [Saudi Arabia Yanbu Seawater Desalination Project] Introduction of supporting Songjiang EPDM rubber joints:

1. Economical

①Compared with mechanical expansion and packing shock absorption, rubber joints occupies a small space, is light in weight, easy to install and disassemble, save labor, and low cost.

②For the same limited capacity, there is no need to increase the pump and pipe diameter. The inner wall of the rubber joint is smooth, which reduces the resistance of the fluid and does not damage the pipe body.

③With good water tightness, no pads are needed during installation.

④Wide scope of application: Choose different rubber formulations to make the product have various properties such as heat resistance, oil resistance, corrosion resistance, aging resistance, abrasion resistance, and ozone resistance.

⑤Wide temperature resistance range: reasonable formula (material) can make the temperature resistance range of the product reach: -15c°-110C°

2. Displacement

Good elasticity, good adaptability to compression, stretching, twisting, vertical displacement of deflection, etc., to prevent damage to the pipeline system due to thermal expansion and contraction deformation or uneven foundation settlement.

3. Vibration reduction and sound absorption

①The sphere is made of rubber material with great damping, which can effectively buffer vibration, suppress and reduce mechanical vibration, and absorb the impact noise of fluid.

② Reasonable installation between the vibrating machine and the metal pipe can reduce the noise transmitted by the structure

4. Pressure resistance

①Multi-layer sphere structure. It is not suitable for withstanding internal pressure, has strong blast resistance, good impact resistance, and does not deform under external pressure.

②The working pressure is 0.6MPa, 1.0MPa, 1.6MPa and 2.5MPa.

5. Reducibility of rubber joints

① After being compressed by force, it can be restored to the original state after removing the external force.

②When the metal retractor is completely compressed, it will form a fixed shape and will not recover.

6. Wide application range

①Suitable for indoor installation

②Suitable for outdoor installation (UV protection is required)

③Suitable for buried installation (need to be buried device)

3. [Saudi Arabia Yanbu Seawater Desalination Project] Introduction to Songjiang EPDM rubber joint project:

1. A large-scale renewable energy desalination plant in Saudi Arabia is a joint venture between IBM and Saudi Arabia’s main research and development institution-Abdullah (KACST). Located in the northeastern city of Al Khafji, the plant will use ultra-high concentration photovoltaic power generation technology (UHCPV). After completion, it is expected to provide 30,000 cubic meters of potable water for 100,000 people a day. This joint venture project will improve the quality of polymer membranes through nano-film purification technology to improve seawater desalination efficiency and reduce costs.