Taixing Binjiang Sewage Treatment Plant-Rubber Joint

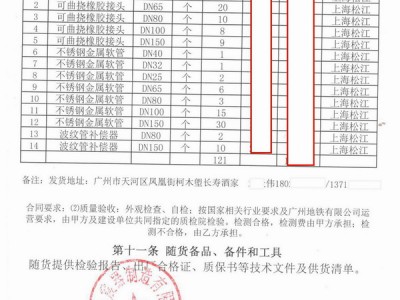

Shanghai Songjiang Shock Absorber Group Co., Ltd. provided Shanghai Songjiang rubber joints, Shanghai Songjiang metal hoses, Shanghai Songjiang expansion joints and other products for Taixing Binjiang Wastewater Treatment Plant in 2015. The quality is stable and reliable, and the quality is superior!

The following photos are provided by the engineering department of Shanghai Songjiang Shock Absorber Group: All are real photos, please do not reprint, thank you for your cooperation!

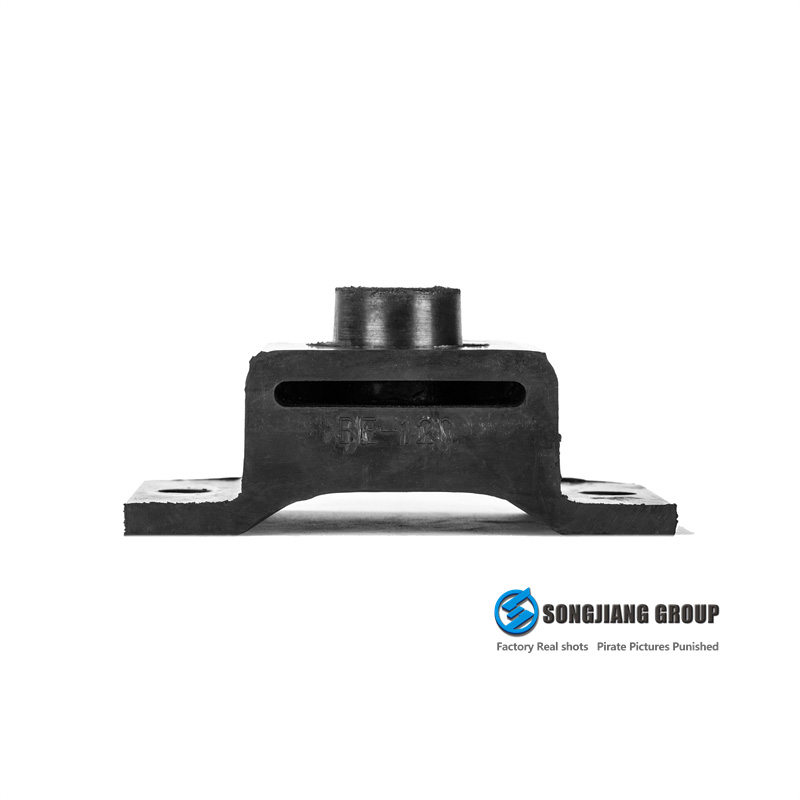

The products installed here are Shanghai Songjiang DN600 rubber joint products:

Installed here are Shanghai Songjiang DN500mm rubber joint products:

The products installed here are all Shanghai Songjiang stainless steel metal hose products:

All the expansion joints installed in this pump room are Shanghai Songjiang stainless steel expansion joints:

The Network Department of Shanghai Songjiang Shock Absorber Group will introduce to you that the Taixing Binjiang Sewage Treatment Plant is the polluted (waste) water discharged from the pollution source. Due to the high total amount or concentration of pollutants, it does not meet the discharge standard requirements or does not meet the environmental capacity. Requirements, thereby reducing the water environment quality and functional goals, must be artificially enhanced places. Generally, it is divided into urban centralized sewage treatment plants and various pollution sources scattered sewage treatment plants, which are discharged into water bodies or urban pipelines after treatment. Sometimes in order to recover and recycle wastewater resources, it is necessary to build wastewater reuse or recycling wastewater treatment plants when it is necessary to improve the quality of the effluent after treatment. The treatment process of the treatment plant is an optimized combination of various commonly used or special water treatment methods, including various physical methods, chemical methods, and biological methods. It requires advanced technology, reasonable economy, and low cost. The design must implement the current construction guidelines and policies. Therefore, from the treatment depth, the sewage treatment plant may be **, 2*, 3* or advanced treatment. The design of the sewage treatment plant includes a variety of different treatment structures, auxiliary buildings, the plane and elevation design of the pipeline, and the design of roads, greening, pipeline integration, plant water supply and drainage, sludge disposal and treatment system management automation to ensure sewage treatment The plant achieves various requirements such as stable treatment effect, meeting design requirements, convenient operation and management, advanced technology, and low investment and operating costs.

Sewage treatment (sewage treatment, wastewater treatment): The process of purifying sewage to meet the requirements of a certain water body for drainage or reuse of water quality. Sewage treatment is widely used in various fields such as construction, agriculture, transportation, energy, petrochemical, environmental protection, urban landscape, medical treatment, catering, etc., and more and more come into the daily life of ordinary people.

The following is the introduction of Shanghai Songjiang rubber joints:

1. Material of each part:

1. Inner glue: NR, NBR, EPDM

2. Outer layer glue: NR, NBR, EPDM

3. Main frame: nylon cord (similar to the material inside the tire)

4. Pressurized ring: high-pressure steel wire rope

5. Flange: carbon steel Q23* (forged) surface sprayed with anti-rust paint, stainless steel 304, stainless steel 316L, PVC material)

2. Choosing different rubbers can play different roles:

1. Natural rubber NR (over water)

2. EPDM (acid and alkali resistance, corrosion resistance, power plant desulfurization, lime slurry, coal gas, etc.)

3. Nitrile rubber NBR (oil resistance, including hydraulic oil, aviation kerosene and other oils, high temperature resistance)

4. Wear-resistant rubber TZ (wear-resistant, generally used in the mineral industry, granular medium conveying pipelines)

5. Kinds of rubber (emulsion, sulfuric acid, etc. special medium)

6. Lined with tetrafluoroethylene (lined with polytetrafluoroethylene material, can resist strong acid, strong alkali, emulsion, *sulfuric acid, wear resistance, high temperature resistance*, low temperature resistance 100 degrees, etc. Special industrial and mining environments)

Three, the advantages of rubber soft joints:

It has high pressure resistance, good elasticity, large displacement, balanced pipeline deviation, vibration absorption, good noise reduction effect, convenient installation, and can greatly reduce the vibration and noise of the pipeline system, and can fundamentally solve the interface displacement of various pipelines , Axial expansion and contraction and other problems. The rubber raw materials are characteristic rubbers with good sealing performance, light weight, convenient installation and maintenance, and long service life, but avoid contact with sharp metal instruments to avoid puncturing the sphere.

Link to this article: https://www.songjiangflex.com/case/taixing-binjiang-sewage-treatment-plant-rubber-joint/