Shanghai Songjiang Shock Absorber Group Co., Ltd. supplied the air duct compensator products for Zibo Steel Plant in 2013. We are the air duct compensator manufacturer of Shanghai Steel Plant. We have production experience and design R&D team. Factory Tel: 13032112360

1. [Zibo Steel Plant Project] Introduction of using Shanghai Songjiang air duct compensator:

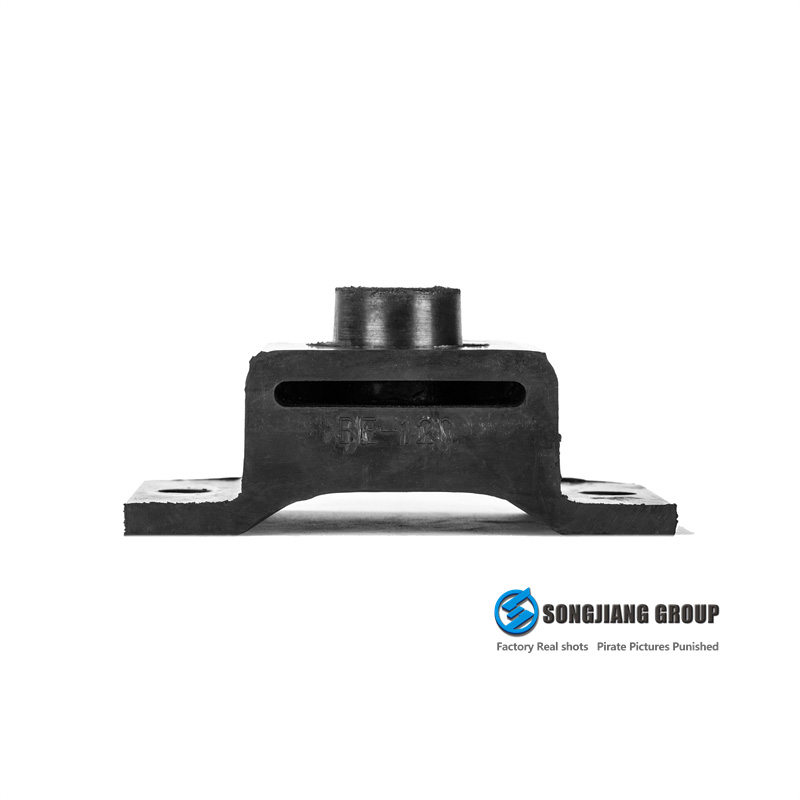

1. The square air duct compensator product used by Zibo Steel Plant.

2. Air duct compensator material: silicone rubber.

3. The temperature of silicone rubber: 300 degrees high temperature.

4. The function of the compensator: shock absorption and a connecting piece of the air duct.

5. Square, round, length, we can customize production.

6. General delivery time: 20 days.

7. Manufacturer Tel: 130321112360

2. [Zibo Steel Plant Project] Using Shanghai Songjiang Air Channel Compensator Performance:

1. Rubber and fiber fabrics have good reproducibility of repeated displacements (changes), can provide large multi-dimensional compensation in a smaller size range, and can better eliminate the multi-directional errors generated during the installation and connection of various pipelines.

2. Rubber and fiber woven have superior sound absorption and shock isolation function, which can effectively reduce and eliminate the transmission of sound and vibration of boilers, fans and other systems.

3. The weak transmission loss of rubber and fiber weaves reduces the design process without adding other auxiliary facilities.

4. Rubber and fiber woven and thermal insulation materials have high heat and corrosion resistance, never rust, and reduce maintenance costs.

5. Rubber and fiber weave have excellent air tightness and flexibility, which can ensure that the conveying medium does not leak and restores to its original state after repeated displacement.

3. Introduction of Zibo Steel Plant:

1. The company originally had steelmaking branch, wire rod branch, machinery factory, Zibo Shuangli Casting Co., Ltd. and other major production units. In March 2003, the company was acquired by Zibo Wanjie Group, a large enterprise group, ranked .232 among the top 500* enterprises, and embarked on the road of reorganization. In the next few years, various indicators have hit historical highs.

2. Steelmaking branch: The steelmaking branch is equipped with two fully hydraulic elevated high-power eccentric hearth (EBT) 30t electric arc furnaces, two 35tLF ladle refining furnaces, and a third-rate R6m progressive arc continuous caster* Sets, each of 800m3/h, 900m3/h oxygen generators, and 35KV substations; realizes microcomputer automatic control of full continuous casting production, with an annual output of 150mm×150mm, 120mm×120mm, for carbon steel billets and reinforced concrete 350,000 tons of billets for hot-rolled ribbed steel bars;

3. Wire rod branch: The existing short-stress wire rolling mill in the wire rod branch is a domestic short-stress rolling mill built in the late 1980s. It was a brand-new wire rod rolling process in China at that time. The output, consumption, and finished product rate all have the advanced level of the same type of equipment in China; annual output of φ6, φ6.5, φ8 carbon steel, welding rod steel, alloy steel, high carbon steel 350,000 tons;

4. Zigang Machinery Factory: owns more than 40 sets of advanced metal cutting and production equipment such as CA8463 roll lathe, B5050 slotting machine, C61100 heavy-duty lathe, plate shearing machine, and plate bending machine. It can undertake the design, production and installation of various metallurgical equipment. .

5. The company originally had steelmaking branch, wire rod branch, machinery factory, Zibo Shuangli Casting Co., Ltd. and other major production units. In March 2003, the company was acquired by a large enterprise group, Zibo Wanjie Group, ranked 232 among the top 500 Chinese enterprises, and embarked on the road of reorganization. In the following years, various indicators have hit historical highs. At the beginning of 2005, Zibo Coking Company was placed under the management of Zigang Company. In August, Wanjie Group’s new refractory plant and Fangzheng Machinery Manufacturing Co., Ltd. were placed under the management of Zigang Company, which further extended the industrial chain of Zibo Iron and Steel.

6. Zibo Iron and Steel Co., Ltd. has major production units such as a steelmaking branch, a wire rod branch, a machinery plant, and Zibo Shuangli Casting Co., Ltd. Zibo Iron and Steel Co., Ltd. was established in 1968, formerly known as the large-scale enterprise Zibo Steel Plant. Now it covers an area of 360,000 square meters and has total assets of 720 million yuan, of which the net value of fixed assets is 360 million yuan.

4. Introduction to other steel plants in Zibo:

1. Shandong Iron and Steel Group Zibo Zhang Steel Co., Ltd. is located in Zibo City, an open coastal city in Shandong Province. It is a large iron and steel enterprise, one of the *local key iron and steel enterprises*, an ISO9001 quality system certification enterprise, and an advanced collective of all* iron and steel industry. The corporate headquarters is located at No. 176 Jinjing Avenue, Zhangdian District, Zibo City, and the new area is located at No. 9 Shihua Road, Huantai Economic Development Zone, Zibo City. The enterprise has the right to import and export, mainly engaged in steel (hot rolled round steel, hot rolled ribbed steel bar, high-speed wire rod), steel billet, pig iron, ore, slag powder, limestone, metallurgical furnace charge, slag powder, metallurgical equipment manufacturing and installation, and power generation And real estate development.

2. The enterprise has 1 million tons of high-strength bar production lines*, two 600,000 tons of high-speed wire production lines, one 120-ton converter, one 1,350m3 blast furnace, one 400,000-ton slag powder production line, and several sets of metallurgical machinery processing and manufacturing equipment. The main product specifications are Φ16~40mm hot-rolled ribbed steel bars for reinforced concrete, Φ16~22mm hot-rolled round steel bars for reinforced concrete, Φ16~50mm hot-rolled round steel bars, Φ5~20mm hot-rolled round steel wire rods, Φ6~14mm heat Rolled ribbed steel wire rod, Φ5.5~22mm cold heading steel hot rolled round wire rod, etc. The main steel grades include plain carbon steel, high-quality carbon structural steel, low-alloy high-strength structural steel, alloy steel, spring steel, cold heading steel, welding steel, etc. Among them, HRB400 products have been awarded the “Quality * Yue” product of China*Metallurgy Honorary title, HRB400 Φ16~32mm hot-rolled ribbed steel bar for reinforced concrete was awarded the gold cup award for the physical quality of metallurgical products.