Product

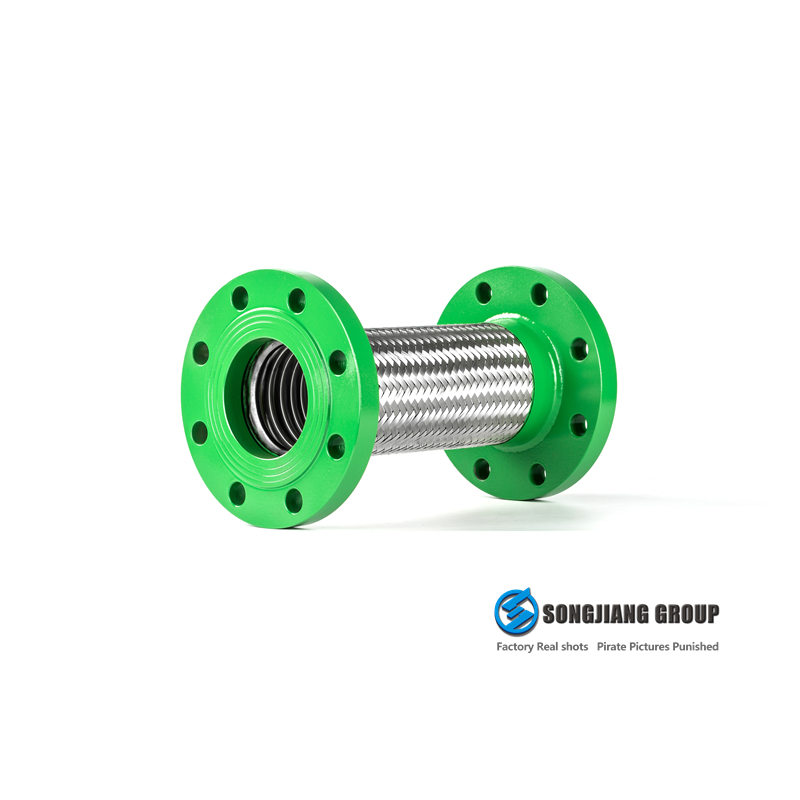

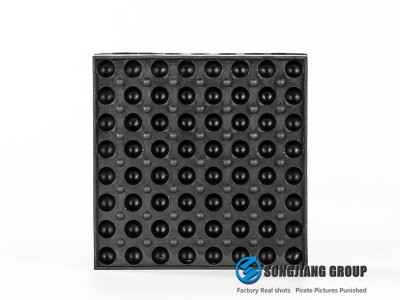

Songjiang Group JTW Flange Matel Expansion Joint

The length can be customized!

Model: JTW-DN80

Diameter: 80MM/3Inch

Pressure capacity: 1.0Mpa/1.6Mpa/2.5Mpa

Songjiang Group strictly implements raw material standards and strictly controls the production process. The JTW stainless steel metal hose is resistant to corrosion, high temperature, low temperature, light weight, small size and good flexibility.

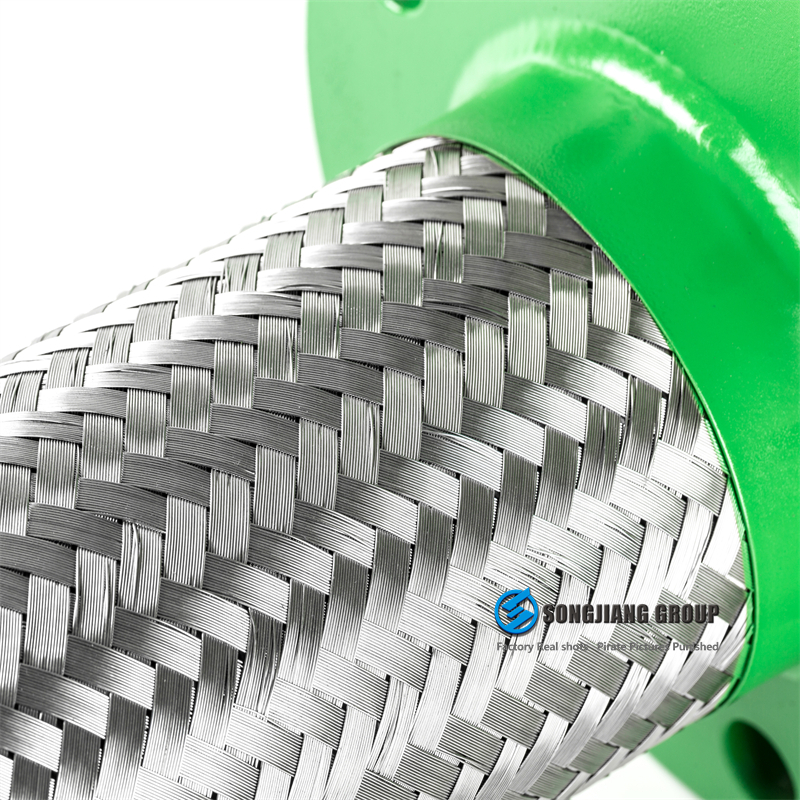

The main parts of production material is austenitic stainless steel hose, thus ensuring the heat resistance and excellent corrosion resistance of the hose, the hose working temperature range is very wide, use the hose on pipeline through corrosion for stainless steel plates, to ensure that the corrosion resistance of hose.

- metal hose is made of 1Cr18Ni9Ti stainless steel, which has strong corrosion resistance.

- hose body is thin-walled stainless steel tube hydroforming. It has strong flexibility, flexibility, bending and anti-vibration ability, strong protection of the woven mesh sleeve, so that it has higher bearing capacity.

- hose can also be made into other connecting methods other than the thread and flange standard, which is convenient for connection and use.

- the product is not only suitable for the matching of rotary joint, but also widely used in the soft connection of a variety of fluid media. Corrosion resistance, high temperature resistance, low temperature resistance, light weight, small volume and good softness. Widely used in aviation, aerospace, petroleum, chemical, metallurgical, power, paper, wood, textile, construction, medicine, food, tobacco, transportation and other industries.

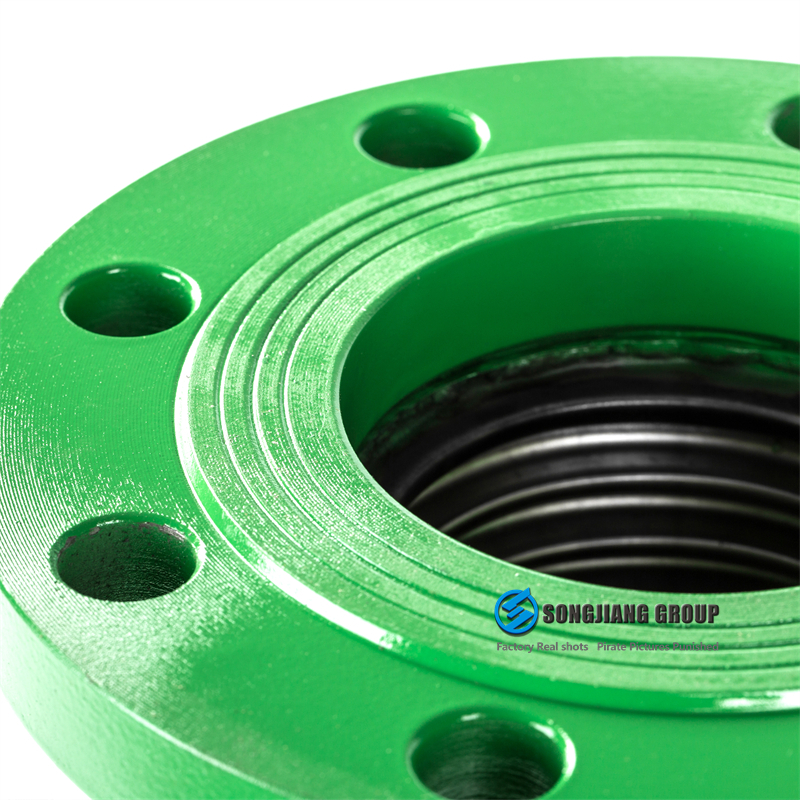

Mechanical damage flange seal face.

Advantages:

1, flexible hose between the metal hose pitch, and the bending radius is small.

2, the metal hose has good scalability, no blocking or rigid.

3, The weight of the metal hose is light and the caliber is consistent well.

4, soft, flexible, flexible, flexible, flexible.

5, the metal hose is resistant to corrosion and high temperature resistance.

6, metal hose anti mouse bite, wear resistance, prevent the internal wire from wear.

7, metal hose bending resistance, tensile properties, anti lateral pressure resistance.

8, the metal hose is soft and smooth, easy to wear line installation and positioning.

9, The flexible hose fittings of the metal hose are easy to connect with the instrument and equipment.

Connect Ways:

1, thread type: the joint of metal hose with a diameter of less than 50 millimeters is mainly threaded. Under the condition of high working pressure, the inner and outer taper surfaces of the two joints are closely matched to achieve the seal after tightening the thread. The cone angle is generally 60 degrees and also useful in 74 degrees. The structure is well sealed, but the concentricity of the two butt parts must be ensured when the installation is installed. In order to solve the problems that are often seen in the actual project, such as repeated dismantling, loading and not easy to be concentric, the joint can be designed to match the cone with the ball head.

2, flange plate: a metal hose joint with a diameter of 25 millimeters. Under the general working pressure, it is mainly made of flanges, and it is sealed in the form of tenon grooves. The two body is connected under the action of the fastening bolt pulling force, which can be rotated along the radial direction and can also be slid along the axial direction. The structure has good sealing performance, but it is difficult to process, and the seal face is easily bruised. Special occasions in need of quick release, can be cut through the bolt fastening holes, made quick detachable flange.

3, fast type: the joint of all kinds of metal hose with the diameter of less than 100 millimeters is generally used fast under the condition of demanding fast loading and unloading. It is often used to seal the “O” – shaped seal made from fluoroplastics or special rubber. When the hand moves a certain angle, the claw, which is equivalent to the multi head thread, is locked; the tighter the “O” ring is pressed, the better its sealing performance. The structure is most suitable for fire, battlefield and other occasions which must be quickly loaded and unloaded. In a few seconds, a group of joints can be butted or disassembled without the need for any special tools.

JTW type Flange stainless steel Expansion Joint installation method

Although the metal hose is compressible and stretchable, it will quickly break and reduce the if it is not installed in the correct position.

The hose can be installed horizontally or vertically or vertically. The most ideal state is vertical installation. At the same time, it should avoid installing near the wheel, and install baffle when necessary.

General can be divided into 3 kinds of metal hose length: first compression length, which is compressed to the limit position of the hose length; the second is to install length, which is in the middle position of the half length of the hose of the maximum displacement; third is the stretched length of the hose is stretched to the maximum when the length of.

When the hose is installed, the hose should be in the middle position, that is, the so-called installation length. When installed in this position, there will be 2 moving directions when the hose is subjected to axial load. Otherwise, if it moves in 1 direction, it will affect the strength and reduce the of the metal hose.

In the actual installation process, considering that the length of hose should be measured according to the result of the ruler, then the installation may affect the production efficiency. Some foreign producers directly install the ruler on the hose and cut the ruler after installation.

1, in the selection of metal hose, for easy installation, please choose a metal hose with a loose flange at one end as much as possible.

2, the surface of metal hose should be protected during the welding operation on the construction site, so as to prevent welding slag and metal hose with arc ignition.

3, The metal hose is strictly forbidden to be twisted and installed.

4, should not bend along the root of a metal hose, and should not have a dead bend.

5, through the medium of corrugated pipe material has no corrosion, chloride ion content in the medium should be less than 25PPM

6, the installation of the correct installation method is strictly installed. (check Installation Guide)

7, Strictly prohibit the seal face of mechanical damage flanges.

Manufacturer: Shanghai Songjiang shock absorber Group Co., LTD

Qualification certificate: certificate of quality, warranty, inspection report, national type test report, third-party performance test report, material report.

Link to this article: https://www.songjiangflex.com/product/dn80-6/