[Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints

The Frequently Asked Questions section of the official website of Shanghai Songjiang Shock Absorber Group Co., Ltd. will share with you some frequently encountered problems related to rubber joints, spring shock absorbers, and metal hose products, and help you to have a correct understanding and further understanding of the products. Let the advantages of the product be brought into full play. The following is an analysis report on the pull-out problem of threaded rubber joints.

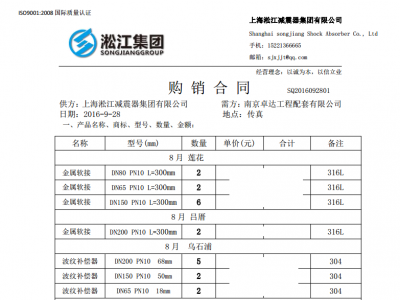

At 17:24 pm on August 30, 2020, I received feedback and pictures from a construction site. Customers reported that one of the DN65 threaded rubber joints had a rubber body exploded, but the rubber body was actually pulled off (see Figure 1). Our factory arranged personnel to arrive at the site at 10:30 in the morning on September 1, 2020 to check the situation. After checking the installation situation, it was found that the threaded installation was misaligned (see Figure 2), and the pipe elbows were not effectively fixed (see Figure 2). Three, four, five), the replaced thread is not fastened in place (Figure 6).

Cause Analysis:

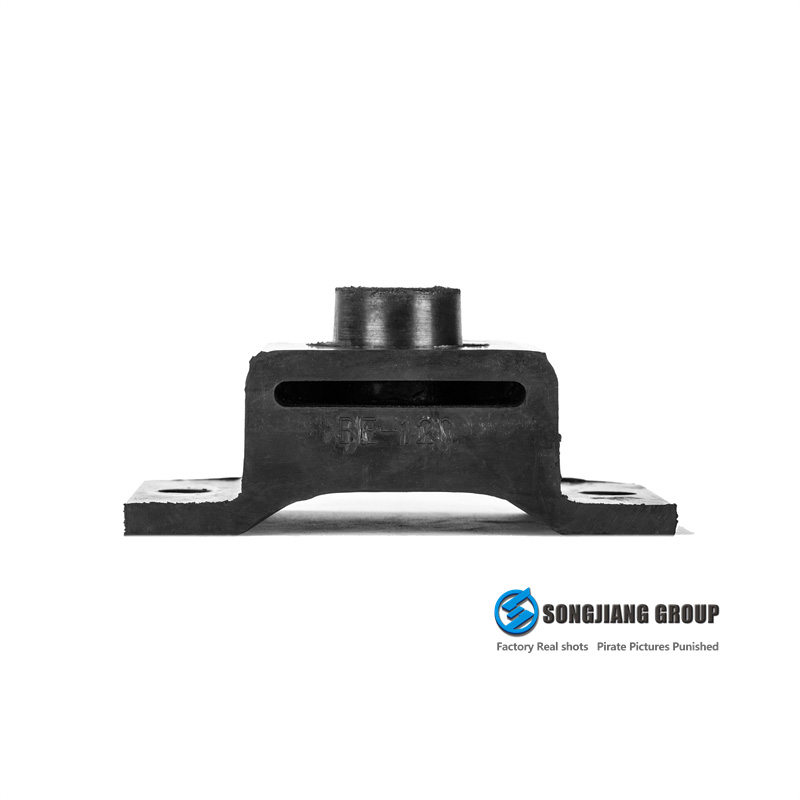

1. During the use of the product, because the pipe elbow is not fixed (see Figures 3, 4, 5), the threaded rubber joint is subjected to the lateral force of the pipe during use (see Figure 7 for the correct method of fixing the pipe).

2. Before cleaning the pipeline two or three times, the threaded rubber joint has not been checked and tightened twice.

Manufacturer’s suggestion:

1. Fix the pipe elbow (marked by the arrow in Figure 2).

2. The threaded rubber joint must be checked and tightened twice before pressing (before pressing means before the first pressure test).

The above is a written analysis report provided by our technology. If you have objections to our products, our factory is willing to cooperate in various tests. If it is our material and our own quality, our factory is willing to bear the inspection fee and replace all product. Shanghai Songjiang Shock Absorber Group Co., Ltd. Technical Department 2020.9.3

![[Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints [Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints](http://www.songjiangjituan.com/uploads/allimg/2009/1-200Z4123641.jpg)

When threaded or flanged rubber soft joints are working, the pipes must be firmly fixed, and they can move along the ends of the pipes, but cannot move laterally, so that the rubber joints can absorb the thermal expansion and contraction of the pipes;

statement:

The extension, compression, deflection, and angle of the rubber joint are all changed when the pipeline encounters thermal expansion and contraction. At this time, the rubber joint plays a real compensation role, instead of being encountered during installation. When the pipeline displacement is reached, the rubber joint is allowed to move rigidly to compensate for the deviation of the static pipeline; then the rubber joint cannot function normally when the pipeline is in a dynamic situation.

![[Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints [Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints](http://www.songjiangjituan.com/uploads/allimg/2009/1-200Z4123641.jpg)

![[Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints [Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints](http://www.songjiangjituan.com/uploads/allimg/2009/1-200Z4131546-50.png)

![[Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints [Frequently asked questions] Analysis report on the pull-out problem of threaded rubber joints](http://www.songjiangjituan.com/uploads/allimg/2009/1-200Z4123641-50.jpg)