The official website of Shanghai Songjiang Shock Absorber Group Co., Ltd. introduces to you: [Case] Information about rubber joints for DN800 drinking water pipeline transformation of Dongguan Tangxia Water Supply Company. Songjiang Group provides environmentally friendly rubber joint products for major water supply companies across the country. For more information, please log in to our official website.

Dongguan Tangxia Water Supply Company was established in 1993. It is a subsidiary of Tangxia Town. It is mainly responsible for the production of the people in Tangxia Town, the supply of domestic tap water, and the sales and installation of tap water accessories. Under the correct leadership and strong support and care of the Tangxia Town Party Committee and the town, the Tangxia Water Supply Company has undergone years of development and growth, and has continuously improved its scientific and technological content. It has developed from one water plant to four water plants. The water supply capacity is 510,000 square meters per day, including 90,000 square meters per day for the central water plant, 250,000 square meters per day for the Phoenix Water Plant, 100,000 square meters per day for the Xiagongyan Water Plant, and 70,000 square meters per day for the Niu Mianpu Water Plant.

The company fully completed the compilation of the town’s community water supply workstations in 2010. The company currently has 287 employees. Over the years, the company has focused on the introduction and training of talents. Among the employees, there are 3 engineers and 12 assistant engineers, with a college degree or above. 108 people.

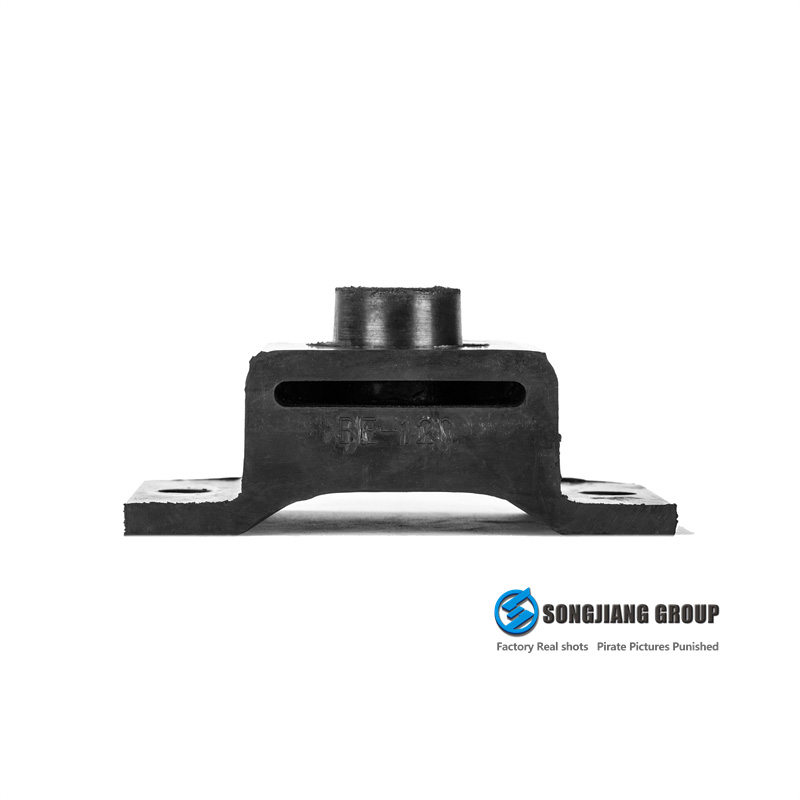

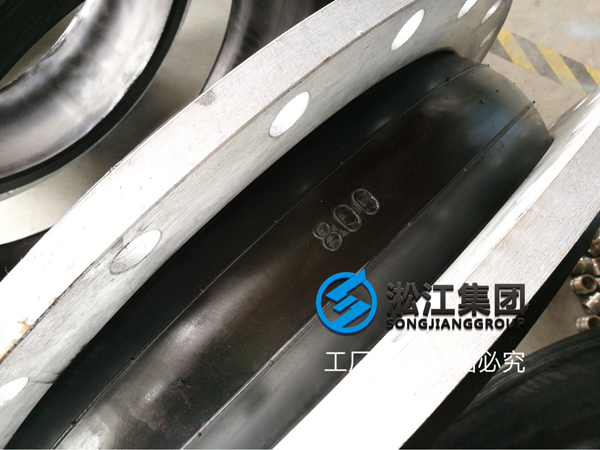

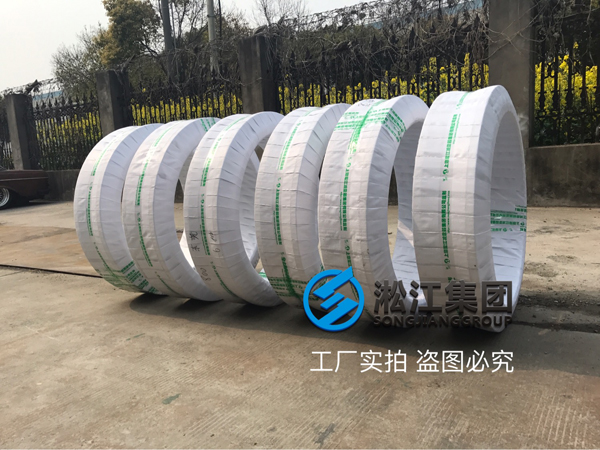

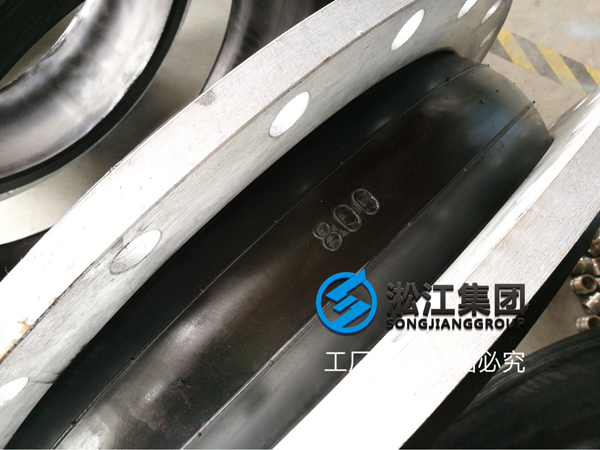

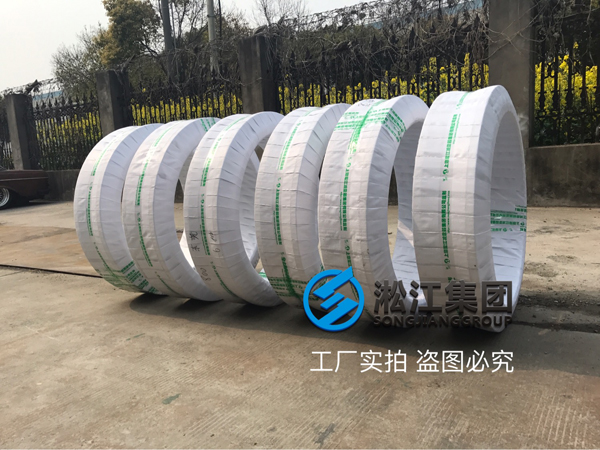

The DN800 drinking water pipeline renovation project of Dongguan Tangxia Water Supply Company selected Songjiang rubber joint products. This product is mainly produced by high-quality environmentally friendly rubber, which effectively guarantees the safety and sanitation of drinking water. The flanges are treated with hot-dip galvanizing. For more long-term anti-corrosion effect, the following is the production and delivery site of DN800 hot-dip galvanized flange rubber joints:

What are the advantages of rubber joints?

1.Small size, light weight, good flexibility, easy installation and maintenance.

2. After installation, it can absorb the lateral, axial and angular displacement caused by the vibration of the pipeline; it is not restricted by the pipeline’s non-concentricity and the flanges are not parallel.

3. After installation, it can reduce the noise generated by vibration of pipeline pumps, etc., and has strong vibration absorption capacity.

4. The internal seamless high-pressure rubber joint can more effectively prevent the corrosion of the inner wall of the rubber joint by the corrosive medium in the high temperature, acid and alkali resistance, and oil resistance pipeline, and improve the service life.

What are the installation precautions for rubber joints?

Precautions

1.When installing a flexible rubber joint in the pipeline, it must be in a natural state and the product should not be deformed artificially.

When the pipeline medium is acid and alkali, oil, high temperature and other special materials, a joint that is higher than the working pressure of the pipeline should be selected.

2.The flange connecting the rubber joint should be a valve flange or a flange conforming to GB/T9115.1 (RF).

3. The normal applicable medium for flexible rubber joints is ordinary water at a temperature of 0-60°C. For special media such as oil, acid, alkali, high temperature and other corrosive and hard texture conditions, the corresponding material rubber joint should be selected. , Can not be used blindly or universally.

4. When the flexible rubber soft joint is used at the inlet and outlet of the water pump, it should be located on the side of the water spring, and a metal reducing joint should be installed between the water spring and the large diameter source of the variable diameter.

5. When the pipeline displacement is greater than or equal to the maximum compensation amount of the joint, the number of joints should be increased to parallel the displacement. It is strictly forbidden to adjust the excess tolerance of the pipeline, so that the joint is in a state of limit deflection displacement and deviation, not to exceed the limit ( (Expansion, displacement, deflection, etc.)

6. For high-rise water supply or suspended water supply, the pipeline should be fixed on the hanger, bracket or anchor frame, and the joint should not be allowed to bear the weight and axial force of the pipeline itself, otherwise the joint should be equipped with an anti-pull-off device (its bearing force must be greater than that of the pipeline Axial force).

7. When installing the rubber joint, the screw of the bolt should extend to the outside of the joint, and the bolt on the end face of each flange should be tightened repeatedly and evenly according to the method of diagonal pressure to prevent pressure deviation. Threaded joints should be tightened with a standard wrench evenly. Use the afterburner stalk to force the joint to slip, slip and break, and check it regularly to avoid loosening and causing peeling or water seepage.

8.After the rubber soft joint is subjected to pressure for the first time (such as: installation pressure test, etc.) or before being deactivated for a long time and then activated again, the bolts should be re-pressurized and tightened and then put into operation.

9. The use or storage of rubber soft joints should avoid high temperature, ozone oil and acid-base environments. Sunshades should be built for pipes used outdoors or sunny and windy. The surface of the joints should be tight. Painted. And winding insulation materials. Due to the aging problem of rubber products, they should be checked and replaced in time.

10. The flexible rubber joint should be installed strictly, exceeding displacement, and limited.

11.The installation bolts should be symmetrical and tightened gradually to prevent local leakage.

12.When the rubber joint is installed on a flat ground, suspended in the air, or vertically, the actual working axial displacement pressure of the rubber joint should be less than the supporting force of the pipeline, otherwise an anti-pull device should be installed to prevent the work from being pulled off under pressure.

13. Rubber joints should be far away from heat sources, ozone areas, and strict. Strong radiation light exposure. Exposure and use of media that do not meet the requirements of this product.

14. When the rubber joints are transported, loaded, unloaded, and installed, be strict. Sharp instruments scratch the surface sealing surface. 6: When installing products above DN200MM, please use the butterfly valve special flange or small-diameter flange to prevent accidents after installation. Lan pull off, water leakage, water seepage phenomenon.

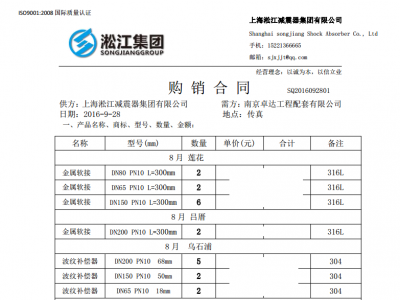

The following is the actual contract shot, please do not reprint, please do not modify: